PEGW Series Low Profile Linear Guide

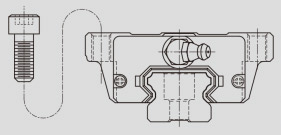

PEGW-SA / PEGW-CA lm guideways types mean low profile flange balls type linear guide, S refers to medium load and C means heavy load capacity, A means bolt mounting from top. Low friction linear slide designed with four row steel balls in arc groove structure which has high load capacity in all directions, high rigidity, self-aligning, can reduce the installation error of mounting surface, low friction linear bearings are widely used for small equipment . PEGW-SA / PEGW-CA block and raitype

PEGW-SA / PEGW-CA block and raitype | Type | Model | Block Shape | Height (mm) | RaiMounting from Top | RaiLength (mm) | |

| Flange block | PEGW-SA PEGW-CA |

| 24 ↓ 48 |  | 100 ↓ 4000 | |

| Application | ||||||

|

| |||||

linear rail guide with bearing block

PYG ® linear rail and carriage are interchangeable , the slide block or guide rail or even the linear guide group can be replaced respectively , the machine platform can operate high precision linear motion smoothly, which can reduce cost effectively for enterprises.

| Model | Dimensions of Assembly (mm) | Dimensions of Block (mm) | Dimensions of Rail (mm) | Mounting bolt size for rail | Basic dynamic load rating | Basic static load rating | Allowable static rated moment | weight | ||||||||||||||||||||||||

| MR | MP | MY | Block | Rail | ||||||||||||||||||||||||||||

| H | H1 | N | W | B | B1 | C | L1 | L | K1 | K2 | G | M | T | T1 | H2 | H3 | WR | HR | D | h | d | P | E | mm | C (kN) | C0(kN) | kN-m | kN-m | kN-m | kg | Kg/m | |

| PEGW15SA | 24 | 4.5 | 18.5 | 52 | 41 | 5.5 | - | 23.1 | 40.1 | 14.8 | 3.5 | 5.7 | M5 | 5 | 7 | 5.5 | 6 | 15 | 12.5 | 6 | 4.5 | 3.5 | 60 | 20 | M3*16 | 5.35 | 9.4 | 0.08 | 0.04 | 0.04 | 0.12 | 1.25 |

| PEGW15CA | 26 | 39.8 | 56.8 | 10.15 | 7.83 | 16.19 | 0.13 | 0.1 | 0.1 | 0.21 | ||||||||||||||||||||||

| PEGW20SA | 28 | 6 | 19.5 | 59 | 49 | 5 | - | 29 | 50 | 18.75 | 4.15 | 12 | M6 | 7 | 9 | 6 | 6 | 20 | 15.5 | 9.5 | 8.5 | 6 | 60 | 20 | M5*16 | 7.23 | 12.74 | 0.13 | 0.06 | 0.06 | 0.19 | 2.08 |

| PEGW20CA | 32 | 48.1 | 69.1 | 12.3 | 10.31 | 21.13 | 0.22 | 0.16 | 0.16 | 0.32 | ||||||||||||||||||||||

| PEGW25SA | 33 | 7 | 25 | 73 | 60 | 6.5 | - | 35.5 | 59.1 | 21.9 | 4.55 | 12 | M8 | 7.5 | 10 | 8 | 8 | 23 | 18 | 11 | 9 | 7 | 60 | 20 | M6*20 | 11.4 | 19.5 | 0.23 | 0.12 | 0.12 | 0.35 | 2.67 |

| PEGW25CA | 35 | 59 | 82.6 | 16.15 | 16.27 | 32.4 | 0.38 | 0.32 | 0.32 | 0.59 | ||||||||||||||||||||||

| PEGW30SA | 42 | 10 | 31 | 90 | 72 | 9 | - | 41.5 | 69.5 | 26.75 | 6 | 12 | M10 | 7 | 10 | 8 | 9 | 28 | 23 | 11 | 9 | 7 | 80 | 20 | M6*25 | 16.42 | 28.1 | 0.4 | 0.21 | 0.21 | 0.62 | 4.35 |

| PEGW30CA | 40 | 70.1 | 98.1 | 21.05 | 23.7 | 47.46 | 0.68 | 0.55 | 0.55 | 1.04 | ||||||||||||||||||||||

1. Rolling circulation system Block, Rail, End Cap, Steel Balls and Retainer 2. Lubrication system Grease Nipple and Piping joint 3. Dust protection system Scraper, End Seal, Bottom Seal, Bolt Cap, Double SealsFor PEGW-SA / PEGW-CA series, we can know the definition of each code as follows: Take size 25 for example:

1. Rolling circulation system Block, Rail, End Cap, Steel Balls and Retainer 2. Lubrication system Grease Nipple and Piping joint 3. Dust protection system Scraper, End Seal, Bottom Seal, Bolt Cap, Double SealsFor PEGW-SA / PEGW-CA series, we can know the definition of each code as follows: Take size 25 for example: